Automatic line for instant coffee: rinsing, filling, capping and sealing – RTS2U

Automatic line for instant coffee: rinsing, filling, capping and sealing – RTS2U

Custom Solution

Location:Milan, Italy

or

Call +39 0362 594502

Description

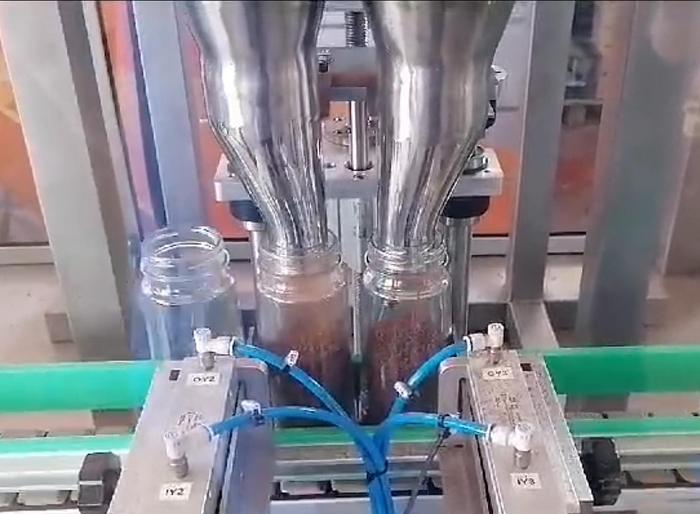

The RTS2U is a complete automatic line designed for packaging instant coffee in 100g jars, combining in one system the stages of blowing, dosing, capping, and induction sealing.

This integrated solution ensures efficiency and food safety.

Main components of the line:

- Rinsing station for container cleaning;

- Vibratory channel dosing system for precise product weighing;

- Automatic capping with integrated cap loader;

- Induction sealing for maximum content protection;

- Reject system for non-compliant sealing;

The entire process is managed via a touch screen panel with memory for over 100 recipes, enabling fast and intuitive format changes.

An M3005T industrial labeller is installed in-line, ideal for wrap-around labelling on cylindrical containers, ensuring precision and consistency in packaging.

Watch the video to see how the RTS2U automates production and boosts the efficiency of your instant coffee line. Production: 1200 pcs/h.

Specifications

| Manufacturer | PMR |

| Stock Number | RTS2U |

| Ideal solution for | coffee - spices - jars with screw and sieve caps - powders - granules. |