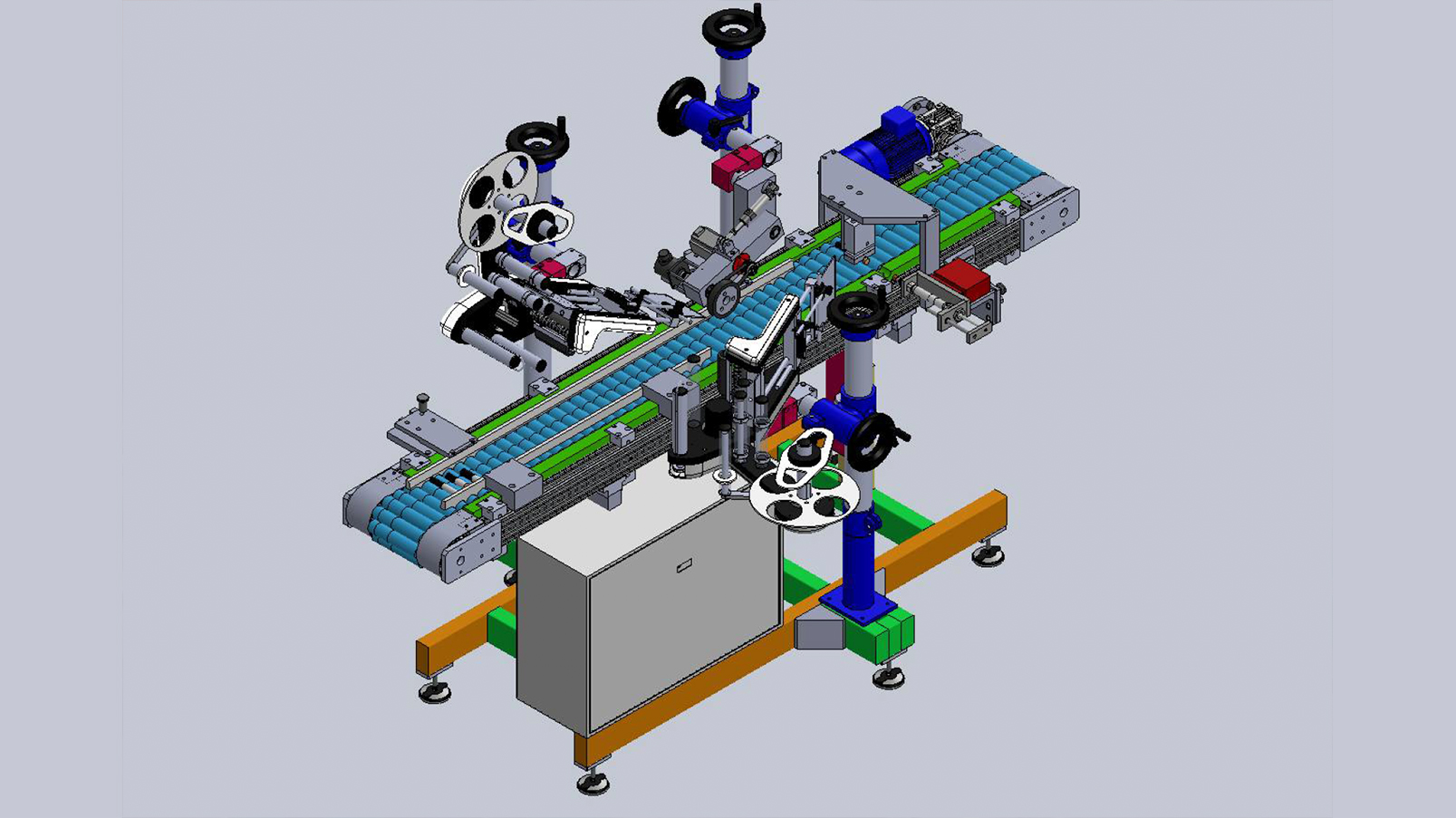

The machine we realized is a labeling line mod. M3010, composed of a head M3000NEW 1 which allows the automatic application of labels having a maximum width of 120 mm.

It is a machine equipped with a stepper motor with variable speed from 4 to 20 meters per minute. In this case our solution provides a photocell for product detection (start) and a specific microswitch for transparent labels stop (stop).

The peculiarity of this solution is the integration of a camera for the detection of a particular product (eg. trademark and logo) and the centering of the label positioned in a predetermined point with respect to the detected particular. To continue, the labeling head mod.SL / PN-CLASSIC NEW 1 that allows the application of the lower sticker.

Through the electronic control unit equipped with touch screen panel, it’s possible the management of the whole functions: speed setting, label dispensing with start andstop function, production counter, survey of silicon paper breaking, storage of 10 formats and the management of possible alarms like end production or machine downtime for emergency.

PMR solution for the labelling of lipsticks and lip glosses proved to be extremely effective allowing the optimization of the production. The easy working operations enabled our customers the improvement of their productivity.