“The cap is a device used to close the opening of a container”. Although the description is simple and brief yet there is an entire world behind this object.

Yes, because the cap plays a secondary part in the mind of a consumer and yet it is one of the main participants in all packaging phases; just think of oenology where the cork can identify a specific wine and even determine its characteristics, or in the cosmetic sector it can enhance the valuableness of the content; however in all areas the correct tightening of the cap is the guarantee of the preservation quality of the purchased product.

The type of caps can vary by structure: crown cap, threaded cap, capsule cap, trigger, and dispenser or by material: cork, synthetic, metal, glass, ceramic or plastic.

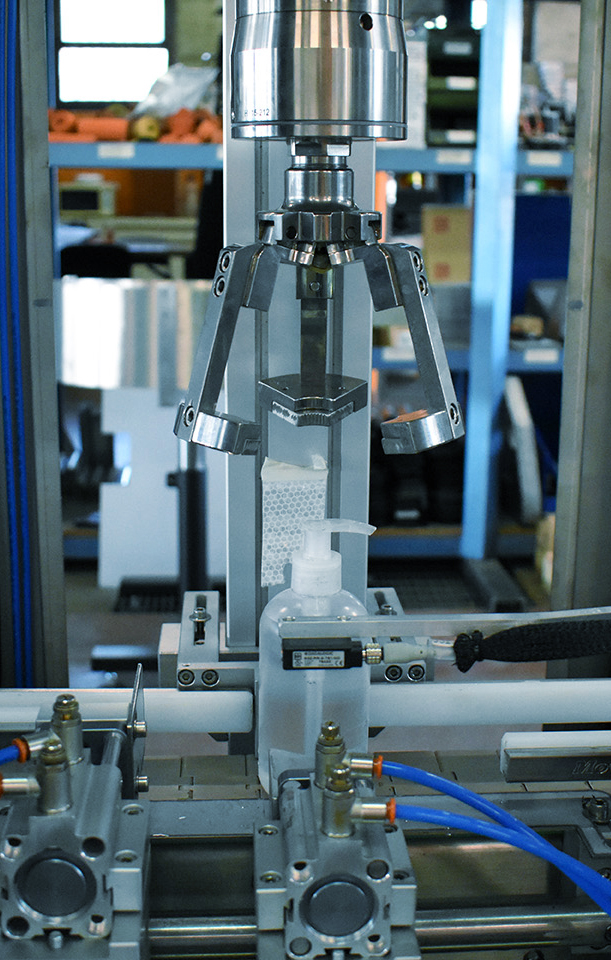

According to all these variations, the capping plants are designed to ensure the highest closure quality while respecting the content and the container.

PMR capping plants cover a very wide range of applications in the sectors for various types of tightening: cosmetics, food, beverage and the pharmaceutical industry.

Our plants are also designed according to productivity: there are semi-automatic bench systems for up to 500 pcs/h and automated systems that exceed even 2000 pcs/h.

These are some of the features that distinguish our automatic capping machines:

- 304 stainless steel structure; if necessary, 316 stainless steel;

- all components necessary for changing the bottle and cap format are fixed with quick release devices and can be replaced without using tools;

- control systems that ensure perfect positioning of the cap on the container, and in the event of a badly placed or missing cap, the bottle is discarded and redirected towards a conveyor belt parallel to the line conveyor belt;

- the feeding of the caps can take place by means of automatic mechanical rotary distributors or pick & place systems;

- the connection between the cap distributor and the capping machine is made by horizontal transport channels with air cushion or motorized belts;

- cap elevators are also available with hoppers of various sizes and therefore suitable for guaranteeing autonomy periods of different duration;

The entire range of PMR capping machines can be supplied as single and independent machines or combined and connected with our filling machines and labelling systems; this modularity allows implementing the system with maximum time flexibility, always guaranteeing perfect communication between the various modules.

.jpg)